Which Wire is Best for House Wiring? 10 FAQs Answered

When we think of home safety, most of us imagine strong doors, secure locks or maybe even fire alarms. But rarely do we think about the hidden network of wires inside our walls. These wires remain invisible, yet they are the very lifelines that power every appliance, fan, light and socket in our homes. They play one of the most critical roles in keeping our homes safe, functional and future-ready.

Despite their importance, house wires are often taken for granted. For most homeowners, buying wires is simply about choosing a brand or checking the price. Electricians and retailers may recommend options, but very few people stop to ask the right questions like what makes one wire safer than another, why certain wires cost more, or how the choice of insulation and copper purity directly affects fire safety and energy efficiency.

In today’s world, the demands on house wiring are increasing rapidly. From heavy-load appliances like geysers, air conditioners and induction cooktops to 24x7 connected devices and smart home setups, wires are under far more stress than ever before. Combine this with rising summer temperatures in India which is often above 45°C, it becomes clear that wires are operating in harsher, hotter and riskier conditions than the standards of yesterday were designed for.

This is why understanding your house wires is no longer optional but it’s essential. Whether you’re a homeowner wanting peace of mind, an electrician ensuring safe installations or a consultant specifying materials for large housing projects, the quality and type of wire you choose can literally make the difference between safety and disaster.

This blog answers some of the most frequently asked questions about house wires. From copper purity and conductor classes to insulation types and grades, these FAQs are designed to make technical topics simple and practical.

Here are the 10 most frequently asked questions about house wires, along with simple, clear answers to help you make safer and smarter choices.

1. What is ETP grade copper in house wires and why is it used?

ETP (Electrolytic Tough Pitch) copper is the most widely used grade for house wires because of its exceptional conductivity, high purity and minimal impurities. This means electricity flows with minimal resistance and lower energy loss. Its excellent drawability and ductility makes it easy to process in fine, flexible strands, ensuring easier installation, better bending and long-lasting performance. ETP copper combines technical excellence with everyday reliability, making it the safest and most efficient choice for home wiring.

2. Why is higher copper purity important for house wiring?

The purity of copper directly affects a wire’s conductivity, safety and lifespan. High-purity copper ensures lower conductor resistance (CR), which means less heat is generated (I²R losses) and electricity flows more efficiently. In contrast, local or recycled copper may look thicker but carries more impurities, leading to higher energy losses, hotspots, reduced appliance performance and even fire risks under heavy load. For example, a ceiling fan wired with impure copper may run slower, heat up or consume more electricity than one connected with pure copper wires. Pure copper wires not only save energy but also protects your home and appliances, ensuring your wiring lasts longer and runs cooler.

3. What does 101% conductivity mean in electrical wires?

Conductivity of copper is measured against the International Annealed Copper Standard (IACS), where pure annealed copper is fixed at 100% conductivity. However, when copper is refined to very high purity (like ETP copper), it can slightly outperform this benchmark, so its conductivity is recorded as 101% IACS.

This doesn’t mean copper is doing the impossible; it simply means the copper being used is purer and more efficient than the standard reference copper. In real life, 101% conductivity wires allow electricity to pass with less resistance, lower heat build-up and fewer energy losses. For your home, that means cooler wires, longer life and safer operation.

4. What is the difference between Class 2 and Class 5 conductors?

The difference lies mainly in flexibility. Class 2 conductors are made of fewer, thicker strands of copper, making them less flexible. They are commonly used in fixed installations, where wires don’t need frequent movement. Class 5 conductors on the other hand are made of many fine strands of copper, making them highly flexible and easier to bend or route through tighter spaces.

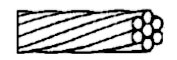

| Conductor Class | Configuration for 1 Sq. mm | Reference image |

|---|---|---|

| Class 2 | 14/0.31 mm (max.) 14 strands each of 0.31 mm (max.) |

|

| Class 5 | 32/0.21 mm (max.) 32 strands each of 0.21 mm (max.) |

|

5. What is Conductor Resistance in house wire and why is it important?

Many people believe you can judge wire quality simply by measuring its diameter and doing a mathematical calculation to estimate resistance. But this is a myth. The only accurate way to check a conductor’s quality is by measuring its D.C. resistance at 20°C using a Kelvin Bridge, as defined in IS 8130 or IEC 60228 standards.

Conductor resistance is not just about the size of copper, it also depends on copper purity. For example, impure or recycled copper may have a bigger cross-sectional area but still higher resistance, which means more heat, more energy loss and shorter wire life. It’s like comparing 18-carat gold with 24-carat gold, the weight may be similar, but the purity makes all the difference. Always check if your wire complies with IS 8130 / IEC 60228 resistance standards, not just its size on paper.

6. What is the difference between Flame Retardant (FR) and Heat Resistant (HR) wires?

Flame-retardant (FR) wires are designed to resist catching fire and to self-extinguish if a flame source is removed. Heat-resistant (HR) wires, on the other hand, can withstand higher operating temperatures without softening, degrading, or losing performance.

In simple terms - FR protects against fire spread, HR protects against heat stress.

We recommend HR+FR wires, which combine both benefits in a single wire. At a slightly higher price point than standard FR wires, HR+FR wires offer higher safety, longer life and better performance in today’s hotter, load-heavy Indian homes.

For more information on HR+FR wires read our previous blog Why Indian Homes Now Need Heat Resistant House Wires?

7. FR vs HR+FR vs LS0H wires – which one should you choose?

FR (Flame Retardant) & HR-FR (Heat Resistant + Flame Retardant) PVC wires are suitable for homes, small offices and residential projects where the risk profile is lower. FR wires resist catching fire, while HR+FR adds the ability to withstand higher operating temperatures, making them safer for modern homes with heavier loads.

LS0H (Low Smoke Zero Halogen) wires are the gold standard for public safety. As per the latest CEA (Central Electricity Authority) regulations, LS0H wires are mandatory in all public buildings such as schools/colleges, hospitals, hotels, malls, airports and even metro stations, irrespective of the building height. In case of fire, LS0H wires emit very low smoke and no toxic halogen gases, ensuring safe and quick evacuation. They are also strongly recommended for high-rise residential buildings, where fire risks are higher and safe escape is critical.

Hence, for homes & residential projects, HR+FR wires are a reliable and economical choice. For public spaces & high-rise buildings, LS0H wires are the safest and future-ready option.

For more information on FR vs HR+FR vs LS0H wires read our blog FR, FRLSH & HFFR Wires - Understanding the Real Difference

8. Do thicker wires mean better safety?

It’s a common belief that a thicker wire automatically means better safety, but that’s not necessarily true. The real safety of a wire depends on both the copper conductor and the quality of insulation.

Some low-cost or local wires use recycled or commercial-grade PVC to make them appear “thicker.” While this adds bulk, it doesn’t add protection. Such insulation often fails critical safety tests like High Voltage Test, Insulation Resistance, Thermal Stability and Mechanical properties.

Worse, these poor-grade insulations may contain lead, mercury and other harmful substances, making them unsafe for people and the environment.

The truth is simple: A thinner wire made with pure copper and high-quality insulation is far safer than a thicker wire made with poor materials. Always look for wires that comply with applicable standards instead of judging by thickness alone.

9. What is the difference between max. operating temperature and max. short circuit temperature of a wire?

Maximum Operating Temperature is the highest temperature a wire can safely carry current continuously without degrading its insulation.

For example, FR PVC wires are rated up to 70°C, while HR+FR wires can go up to 85°C. In LS0H wires, the operating temperature depends on the insulation type. It is 70°C for thermoplastic LS0H and 90°C or more for thermoset (crosslinked) LS0H wires.

Maximum Short Circuit Temperature is the peak temperature the wire can withstand for a few seconds during a fault (like a short circuit). Here, the difference is huge - thermoplastic insulated wires withstand around 160°C, while thermoset or crosslinked insulated wires can handle 250–300°C without failure.

Hence, operating temperature is like your wire’s everyday working limit, but short circuit temperature is its emergency survival limit.

10. What is the difference between Thermoplastic and Cross-linked (Thermoset) insulation?

Wire insulation can be broadly classified as thermoplastic or cross-linked (thermoset). While both protect the conductor, their heat behaviour, structure and durability are very different. The table below highlights the key differences and why cross-linked insulation, whether chemical or E-Beam, offers superior safety and performance.

| Features | Thermoplastic | Cross-linked (Thermoset) |

|---|---|---|

| Structure | 1-dimensional, linear molecular structure | 3-dimensional network structure |

| Behaviour with heat | Deforms and softens under heat | No change under heat |

| Short Circuit Temperature | ~160°C | ~250 to 300°C |

| Current Carrying Capacity | Lower | Higher |

| Durability | Lower dielectric strength. Economical for basic residential use | Excellent dielectric strength. Better thermal, mechanical & electrical stability. |

| Applications | Domestic house wiring, general purpose | High-rise buildings, public places, industrial cables, safety-critical applications |

Generally, halogen free wires available in the market are offered in thermoplastic versions, identified with the code ‘Z’ on the box or packaging. In contrast, thermoset or cross-linked halogen free wires which offer better features, carry the code ‘XZ’, as specified in the Indian Standard IS 17048.

Conclusion:

Choosing the right house wire is not just about price or thickness, it’s about safety, reliability and long-term peace of mind. From copper purity to insulation type, every detail plays a role in protecting your home and loved ones. With the right knowledge, you can avoid hidden risks and make smarter choices. After all, safe wiring today means a safer tomorrow.