The Importance of Solar Cables in Reliable Solar Power Generation

Solar energy is no longer just an alternative, it is becoming the backbone of global sustainable power generation. As solar installations scale from small rooftop systems to multi-megawatt solar farms, one component silently determines their efficiency, reliability and long-term performance - the solar cable.

While panels, inverters or structures often take the spotlight, the humble cable carries the lifeblood of a solar system which is DC electricity. A failure in cables can lead to power loss, hotspots, fire hazards or complete system shutdown. This makes understanding and selecting the right DC solar cables (PV cables) essential for engineers, installers, consultants and even end users.

This blog simplifies everything you need to know about how DC Solar cables to support the future of renewable energy.

Why Solar Cables Matter More Than Ever?

Solar cables operate in one of the harshest outdoor environments:

- Constant UV exposure

- High ambient temperatures

- Moisture, humidity, rain

- Mechanical stress due to wind or installation movement

- Risk of rodent damage

- Ozone & chemical exposure

- Voltage surges and spikes

A typical solar plant is expected to run for 25–30 years, which means the cables must also match this life expectancy without becoming brittle, unsafe or electrically unstable. Ordinary wires simply cannot withstand this for decades. A wrong cable can silently reduce power generation, create hotspots or in the worst case lead to fire hazards. This is where specialized DC solar cables, designed and certified under standards such as IS 17293, IEC 62930 or EN 50618 play a crucial role.

What Makes DC Solar Cables different from Normal Electrical Wires?

(A) Crosslinked insulation and sheath material: Solar cables are engineered for maximum safety, long life and stable performance under outdoor and DC environment stresses. Unlike normal PVC wires, solar cables use electron-beam crosslinked polymers with 3-dimensional molecular structure, that provide:

- Extremely high thermal stability

- No melting or dripping during overload

- Higher insulation resistance

- Zero-halogen low-smoke properties

- Better resistance to UV, ozone, acids and chemicals

(B) Suitable for DC voltage levels: DC behaves differently from AC. It is more unforgiving and causes:

- Long-term thermal stress

- Higher chances of arc formation

- Carbonization of insulation

Solar cables are specifically designed to handle up to 1800V DC, ensuring safe operation.

(C) Flexible Tinner copper conductor: Tinning increases the life by resisting:

- Oxidation

- Corrosion

- Humidity effects

Flexibility of conductor ensures easy routing around structures and prevents internal conductor breakage.

(D) UV & Ozone Resistance: Outdoor exposure can degrade regular cables in just 3–5 years. Solar cables, however, offer 20–30 years UV resistance, making them suitable for all climates.

The role of a solar cable goes much deeper. It is the only component that connects every part of the system - module to module, string to string, array to inverter. In other words, if panels are the face of solar energy, cables are the nervous system that keeps everything alive and stable.

Why Is the Solar Sector Seeing Cable Failures?

Over the last decade, India has seen an unanticipated surge in solar power generation, which has led to enormous demand for solar panels, solar inverters, batteries, performance monitoring systems and not to mention the wires and cables used in this system. However, this rapid growth has also exposed a major industry concern: spurious solar cables flooding the market. A solar plant is designed for 25 years, but many non-standard cables fail within 3–5 years. And when a solar cable fails, it never fails alone, it affects panels, connectors, junction boxes, inverters, and ultimately the plant’s output and ROI. The irony is that solar cables form only about 1% of the project cost, yet they safeguard 100% of the project’s energy flow.

In many installations, EPCs or contractors look for cost savings in components like cables, connectors, or structures. Unfortunately, the temptation to pick cheaper cables leads to:

- frequent shutdowns

- derating of generation

- hotspots and fires

- premature system degradation

- unpredictable maintenance costs

- major losses in GWh (generation) over the years

The risk is massive and the savings negligible.

Case Study: The Hidden Risks Behind Cheap Solar Cables

To understand this better, let’s consider a simple real-world scenario.

A typical 1 MW solar plant requires an investment of around ₹3 crore. The total cost of DC solar cables is just ₹3 lakh which is roughly 1% of the project.

An EPC contractor chooses a cheap, non-standard cable (Cable X) costing ₹3 lakh.

A BIS-certified IS 17293 solar cable would have cost around ₹3.3 lakh which is only ₹30,000 more, which is 0.1% of the total project cost.

On paper, they saved 0.1%. In reality, they lost much more.

Within 3 years:

- insulation started cracking

- UV exposure hardened the jacket

- strings began failing

- connectors overheated

- inverters tripped frequently

- generation losses piled up

- moisture ingress caused faults

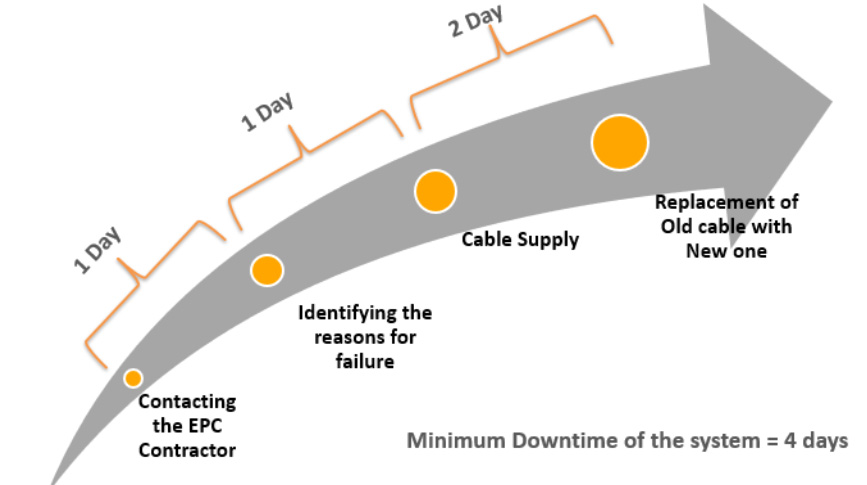

- the plant had to undergo shutdown, cable replacement and reinstallation

The losses quickly escalated into several lakhs, far outweighing the mere ₹30,000 saved at the beginning. These losses included repair expenses, replacement of damaged cables and connectors, potential panel replacement in severe cases and significant loss of energy generation during the downtime.

This case underscores a powerful truth:

saving a small amount on cables can jeopardize the plant’s lifespan, performance, safety and overall return on investment.

QCO: A Mandatory Shift to Safety & Standards

To combat failures caused by substandard solar cables, the Government of India has enforced a Quality Control Order mandating that all DC solar cables must comply with IS 17293 and bear the ISI mark. This ensures uniform standards for UV and ozone resistance, long-term thermal stability, safety and reliability in harsh outdoor conditions.

As India targets 500 GW of renewable capacity, every component, especially cables must uphold global benchmarks. Poor-quality cables can quietly drain gigawatt-hours of energy. The industry must now embrace certified cables, responsible procurement and quality-driven installation practices to secure India’s solar future.

Image: RR Kabel, Trirated DC Solar Cable marked with IS 17293, IEC 62930 and EN 50618

Conclusion

As we push toward a cleaner, greener energy future, one truth stands out clearly: the reliability of every solar plant depends on the quality of its cables. A component that costs barely 1% of the project can determine whether the system thrives for 25 years or fails in just a few. Choosing certified, high-quality, ISI-marked DC solar cables is not just a technical choice, it is a commitment to safety, performance and India’s renewable mission. Because every metre of cable carries more than current; it carries the success of our nation’s solar future.

Note: Images are sourced from Google and used only for educational reference