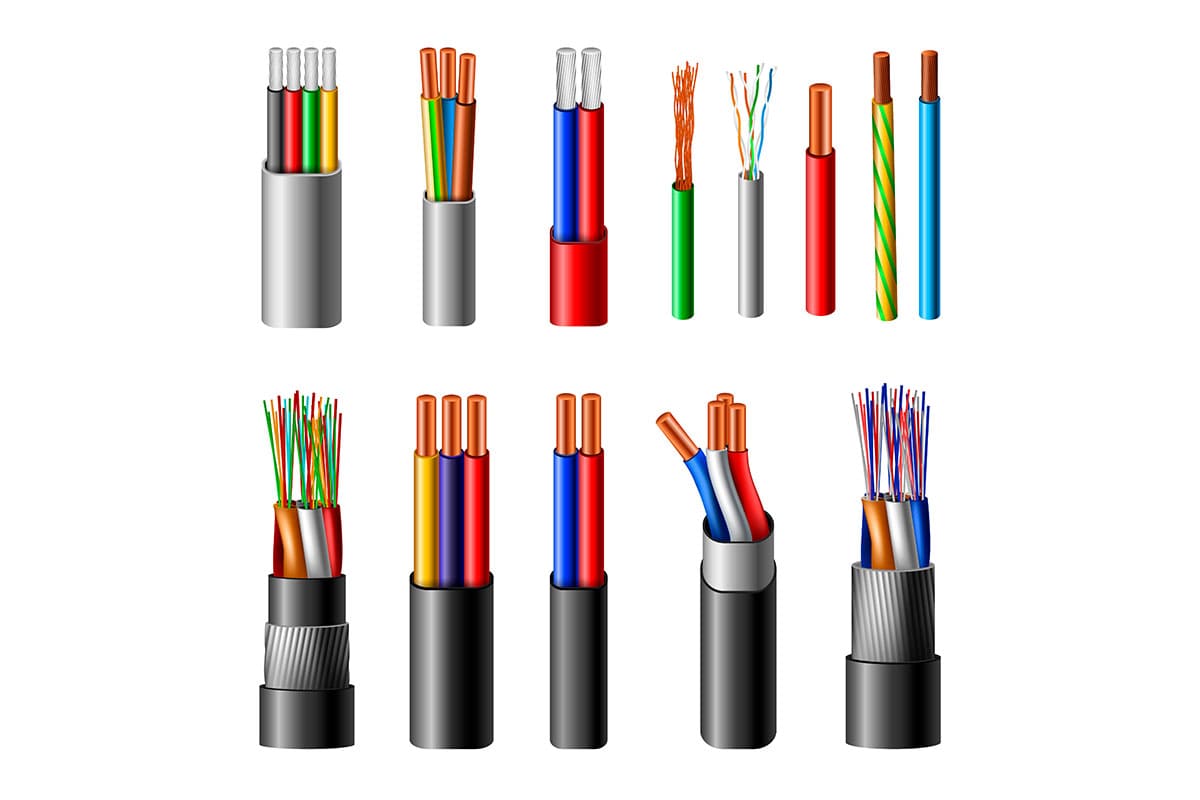

How to Select the Right Wire and Cable for Different Applications

When it comes to electrical installations, selecting the right wire and cable is crucial—not just for performance, but also for safety, reliability, and cost-effectiveness. Whether you're wiring a home, an industrial plant, transmission, distribution or an automotive system, choosing the appropriate cable type ensures optimal operation and long-term durability.

In this blog, we’ll walk through the key considerations for selecting the right wire and cable across different applications.

1. Understand the Application Environment

Before selecting a wire or cable, it's important to assess the operating conditions:

- Indoor or Outdoor: Outdoor installations require moisture resistance and other weather content resistance. It also defined the requirement of mechanical strength in cable.

- Temperature Range: It is very important to define sustainability of function. Wire and cable are available from 60 deg.c to 200 deg.c continuous operation temperature.

- Chemical Exposure: Industrial environments with oils, solvents, or corrosives demand chemically resistant sheaths.

- Mechanical Stress: Areas with bending, vibrations, or abrasion need flexible and rugged cables.

2. Choose the Correct Voltage Rating

Cables are rated for Low, Medium, or High Voltage:

- Low Voltage (up to 1.1 kV): Suitable for residential, commercial wiring, instrumentation, automation, Solar, distribution & other special applications.

- Medium Voltage (1.1 kV – 33 kV): Used in distribution, transmission and industrial power systems.

- High Voltage (above 33 kV): Reserved for transmission networks.

Always match the cable’s voltage rating to the system’s operating voltage to avoid breakdown or fire hazards.

Voltage plays a big role in deciding the conductor and insulation of wire and cable.

3. Select the Right Conductor Material

- Copper: High conductivity, durable, and commonly used in residential and industrial wiring. It is most advisable to use copper conductors only for building / housing wire, instrumentation, Solar, appliances. Pure ETP grade copper conductor conductivity is possible minimum 101%.

- Aluminium: Lighter and less conductivity compared to copper. Mechanical properties are very less compared to copper—mainly used for data centres, power distribution & transmission. Also advisable for light weight application because density of Aluminium is very less compared to copper.

Pure Aluminium minimum conductivity is possible minimum 61%.

4. Consider Current Carrying Capacity (Ampacity)

Ampacity refers to how much current a wire can safely carry without overheating. It depends on:

- Conductor size (cross-sectional area), Conductor types, Insulation types.

- Thermoset insulation is the best for the optimum property of insulation compared to thermoplastic.

- Thermoset compound treated with Electron Beam gives optimum properties of insulation for higher temperature sustainability converted into higher current carrying capacity compared to thermoplastic compound.

- For example, Electron Beam processed thermoset Law Smoke Zero Halogen has higher current carrying capacity compared to thermoplastic Law Smoke Zero Halogen.

- Ambient temperature & maximum possible temperature in function.

- Installation conditions (buried, in conduit, in air etc.)

Use standard tables (like those in IS 3961 or IEC 60287) to select the proper size for your application.

5. Know the Cable Type by Use Case of few example

| Application | Recommended Cable Type |

|---|---|

| House & building Wiring | Single-core wire E-BEAM treated LS0H as per IS 17048. |

| Industrial Control Systems, Appliance | Shielded instrumentation cables, multi-core & control cables |

| Power Transmission | XLPE insulated HV/MV cables, armoured/unarmoured as IS 7098 P-1, IS 7098 P-2, IS 7098 P-3 |

| Automotive Wiring | Low-voltage flexible automotive cables with heat-resistant sheaths |

| SOLAR DC application | E-BEAM treated halogen free UL resistance XLPO insulated and sheathed cable as per IS 17293, EN 50618. |

| Fire-Sensitive & Fire Survival Zones, | Specially designed Fire Survival Armoured Cable as per IS 17505-1. |

6. Safety & Compliance with Standards

Ensure the cables meet national or international standards like:

- IS (Indian Standards): published by Bureau of Indian Standard

- IEC Standards

- UL, BS, or other regional standards

Look for third-party certifications and test reports verifying compliance.

REACH & RoHS compliance must be the criteria of selection for the environment and human safety.

There are many risks associated with non -standard products that can cause very serious electrical accidents.

7. Additional Features to Consider

- Bending Radius of wire and cable against the requirement at application.

- Packing, storage and handling required at application to convert quality manufactured wire and cable into successful sustainable application.

- Method of installation and cabling to avoid any disturbance and accident during application.

- Any additional property subject to the surrounding environment.

- To check, verify and validate the products through test report and testing at laboratory of manufactures and at third party.

Conclusion

Choosing the right wire or cable involves more than just picking a size—it requires a comprehensive understanding of the application, environment, electrical load, and safety standards. By following the above considerations, you ensure a safe, efficient, and compliant installation.

Also need to understand that it is an electric product. It must not be selected as per gravimetric and volumetric property. It must be selected as per the compliance of electric, mechanical and other properties required against application.

RR KABEL can give right advice to select perfect products against each application.

Written by Ronak Bhatt,

General Manager | Technical Cell & Product Management, R R Kabel, May 30, 2025.