FR, FRLSH & HFFR Wires – Understanding the Real Difference

In an age where fire safety, air quality, and human well-being are no longer just priorities but necessities, choosing the right type of wire insulation becomes more than a technical detail—it becomes a responsibility. Among the most common terminologies in the Indian cable industry are FR (Flame Retardant), FRLSH (Flame Retardant Low Smoke and Halogen), and HFFR (Halogen Free Flame Retardant), also commonly referred to as LS0H (Low Smoke Zero Halogen).

Though these terms may seem interchangeable to many, each one represents a unique chemical formulation, flame response behaviour, and environmental impact. Let’s decode the differences that matter.

FR (Flame Retardant) wires are the most basic level of safety-enhanced wires predominantly used in India. These wires are insulated with standard PVC compounds that include flame-retardant additives. Their function is to delay the spread of fire when exposed to flame. However, what’s often not highlighted is that in doing so, they emit thick black smoke and toxic halogen gases, which leads to suffocation, disorientation, reduces visibility and makes evacuation difficult, endangering lives. FR wires, while still permitted, are best suited for low-risk residential environments where occupancy is limited, spaces are well ventilated, and the likelihood of entrapment during fire is minimal.

Moving a notch above is the Flame Retardant Low Smoke Halogen (FRLSH) category which is also referred to as FRLS in some cases. The two terms are used interchangeably in India, although technically “FRLSH” is more descriptive. These wires still use PVC as their base material, but the compound is modified to emit less smoke and lower amounts of halogen gases during combustion. This offers improved visibility and reduced toxicity, making them better suited for environments that demand more safety than what FR can provide. In practical terms, FRLSH wires are the minimum recommended standard for high-rise buildings—typically those over 15 meters or four storeys in height—where evacuation during emergencies becomes more complex. However, they still fall short of eliminating halogen-based emissions.

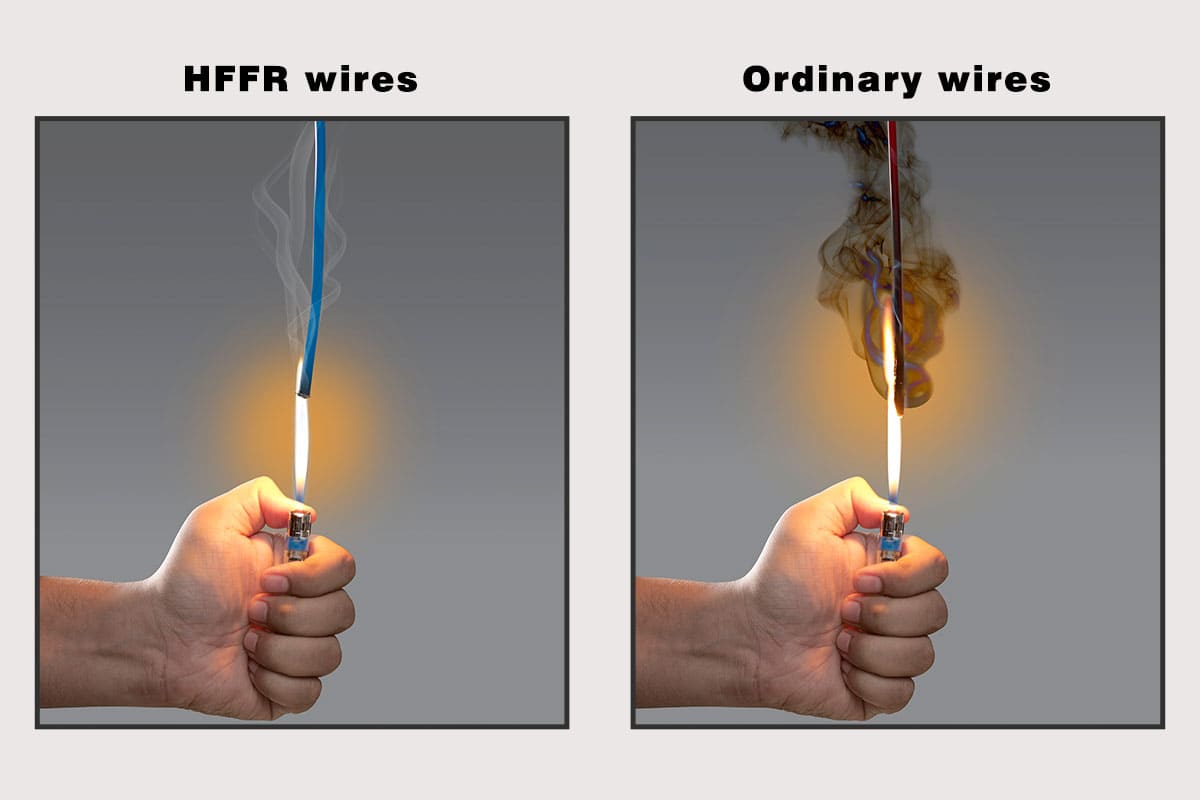

At the forefront of modern wire safety lies the Halogen-Free Flame Retardant (HFFR), also known as Low Smoke Zero Halogen (LS0H) Wires. These wires do not use PVC at all. Instead, they are insulated with specially developed halogen-free polymers, such as polyolefin blends. These compounds offer flame retardancy without releasing harmful halogen gases. In the event of a fire, HFFR wires generate minimal smoke—usually light and white—ensuring clearer visibility and less respiratory damage. More importantly, they do not release corrosive gases, thereby protecting both human life and sensitive electrical equipment like servers, elevators, and emergency systems. Given their performance, HFFR wires are now mandatory for use in commercial buildings such as hotels, hospitals, airports, malls, and any public space—irrespective of their height. Their contribution to health safety, fire response, and sustainable building standards is unmatched.

One additional term often clubbed with these grades is HR (Heat Resistant). This refers to the wire’s ability to withstand higher continuous operating temperatures - generally up to 85°C (as per Indian standards) or 105°C (as per international standards) depending on the grade. While HR enhances the thermal endurance of the insulation, it should not be confused with flame retardancy. A wire labelled HR FR or HR-FRLSH implies that it resists both fire and heat to a certain extent, but unless it is HFFR/LS0H, it will still release halogen gases under fire.

| Parameter | FR | FRLSH / FRLS | HFFR / LS0H |

|---|---|---|---|

| Full Form | Flame Retardant | Flame Retardant Low Smoke Halogen | Halogen-Free Flame Retardant |

| Insulation Material | PVC | Modified PVC | Halogen-Free Polymer |

| Smoke Emission | High (Dense Black Smoke) | Moderate (up to 60% smoke) | Very low(White Smoke) |

| Toxic gas release | High | Reduced(up to 20% acidic gas) | Negligible(Zero Halogen) |

| Corrosiveness | High | Moderate | None |

| Standard | IS 694 | IS 694 | IS 17048 |

| Typical Use | Low-risk homes | High-rise buildings (15m & above) | Hospitals, Airports, Hotels, etc. |

Understanding these differences is not just a matter of compliance but a step toward safer and responsible construction. The choice between FR, FRLSH, and HFFR should not be based solely on cost or availability. It must align with the application environment, occupancy type, and potential fire risk. A high-rise apartment or a metro station cannot afford to rely on FR wires. Similarly, schools, hospitals and auditoriums must avoid halogen-based emissions at all costs, making HFFR / LS0H the only suitable option instead of FR or FRLSH PVC based wires.

Unfortunately, a lack of clarity in the market often leads to suboptimal choices. Retailers and electricians, especially in semi-urban and rural markets, frequently use the terms interchangeably without understanding the underlying chemistry and performance. This is where awareness-building becomes crucial. When specifiers and buyers are equipped with this knowledge, decisions move from cost-centric to safety-centric - ultimately saving lives and protecting infrastructure.

The future of electrical safety lies in smarter choices. HFFR wires present a tangible shift towards safer, cleaner, and more sustainable electrical systems. And as building norms evolve, this awareness will only grow. Whether you're an installer, builder, or end-user, understanding the layers behind insulation isn’t optional anymore - it’s essential.